ABR

Abrasive Die Cutting, knockout & Stacking System

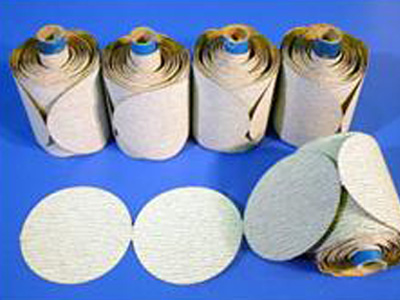

Auto cutting and stacking of jumbo roll abrasive sandpaper material.

Home | Products | Flatbed Die Cutting Serial | ABR

Auto cutting and stacking of jumbo roll abrasive sandpaper material.

| Abrasive |

|